Tom Lenerz

Members-

Posts

338 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Forums

Events

Gallery

Downloads

Blogs

Media Demo

Store

Everything posted by Tom Lenerz

-

This is an important question. Also whiskey? or what type of spirit?

-

We run an external tube-in-shell heat exchanger, I like it a lot.

-

One of the main reasons to have a generator would be if you have a pump on-site for your fire suppression, if the power is out during a storm your building is unprotected for that duration.

-

Return line Above or Below? that is the question

Tom Lenerz replied to SilverSwede's topic in General Discussion

Ours is below as well. It originally had a piece of pipe that returned it to mere inches from the bottom the kettle. With thick rye mashes we would get some backing up, so we shortened the pipe by about a foot, so it still goes well down into the liquid, but we haven't had the problem since. -

Did you double check that they quoted the right number of hours? If that takes one person 11 weeks to do they definitely aren't worth $150 an hour. Maybe it was supposed to be 45? 2 people, 2 and a half days makes a lot more sense, but even that seems high for that short run of pipe.

-

I think it is common that install is usually the same or more as the equipment itself. If the first number is just the boiler, and the $85K includes materials needed for install then maybe? Are there more details on the installation quote, are they doing custom piping and welding or just threading pipe? Is it stainless or black iron, does it include insulation or not... Do they have any competition near you or are you in the middle of nowhere and there is a lot of travel time/expenses allotted? I know around us, all the trades are really busy, so prices for things can be high.

-

This tool is handy... https://www.ttb.gov/formulation/do-I-need-a-formula.shtml

- 10 replies

-

- spiced rum

- ttb

-

(and 2 more)

Tagged with:

-

See this thread, has a link concerning OSHA regs for forklifts in a distillery environment. Spoiler: it doesn’t have to be explosion proof. We had a gas inside at the brewery I worked at and it was ok, we have a gas here but only for outside (mostly for hills). Electric is nice if you remember to charge it because you don’t need to run to swap out tanks in the middle of something and the store is closed. Gas is nice if you are going to be on it non-stop as you can just swap out tanks if you have been using it for 9 hours straight (which we do during harvest).

-

Not an industrial one, but we use this one from TCW. We are happy with it. Only smooths the outlet, not the inlet so the suction hose still jerks around a bit. https://store.tcwequipment.com/products/tcw-pulsation-smoother

-

Why does table 5 PG per pound end?

Tom Lenerz replied to Dry Point Distillers's topic in Federal Gov't

Not sure why it doesn't. However, I never use table 5, I always use table 4. It has much more detail (going down to .1 pound increments instead of 1 pound) and covers the whole range. To get the number in table 5 just divide 1 by the number in table 4. To get PGs or WGs from table 4, you just multiply by the decimal instead of dividing by the number provided in table 5. -

Sorghumrunner, this is in line with what we do. We have a written tank entry procedure and signage modeled off of examples we found on the internet. For our cooker we have additional lock-out instructions and signage because of the agitator and steam nozzle. We have documented staff training of our procedures and have a buddy system for the entrant and the attendant. We log the date, time, oxygen level (from a sensor worn by the entrant), time in the tank, reason to enter, and who entered and who attended. Our attendees are required to stay near the tank during the entry.

-

Understanding impact of Commercial enzymes on Mash Bill

Tom Lenerz replied to Deepak Panwar's topic in General Discussion

Silk, this is interesting info to digest. My limited experience with raw vs. malted barley showed the raw having a major flavor contribution at only 4.5% of the mashbill in a rye whiskey experiment we conducted. It overpowered the malt and corn content, and even competed with the rye for dominance which was about 2/3rds of the mashbill. We have not done much with rye malt yet, so I have nothing to comments there. -

Understanding impact of Commercial enzymes on Mash Bill

Tom Lenerz replied to Deepak Panwar's topic in General Discussion

Silk, what are your experiences with raw vs. malt barley? -

I'm not saying she didn't say that, but the CFR is the law, and the CFR disagrees with that interpretation. I will stick with the CFR. Below is the relevant passage, emphasis is mine. §5.40 Statements of age and percentage. (a) Statements of age and percentage for whisky. In the case of straight whisky bottled in conformity with the bottled in bond labeling requirements and of domestic or foreign whisky, whether or not mixed or blended, all of which is 4 years old or more, statements of age and percentage are optional. As to all other whiskies there shall be stated the following: (1) In the case of whisky, whether or not mixed or blended but containing no neutral spirits, the age of the youngest whisky. The age statement shall read substantially as follows: “___ years old.”

-

Georgeous - The American whiskey industry uses the term "beer gallons" to describe mash thickness for grain-in fermentation and distillation of things like corn, rye, wheat and malt. The reason for this, is most equipment and process can handle one level of mash thickness, and scaling up or down or comparing yields from plant to plant or recipe to recipe is much easier done this way. A beer gallon is the total volume of liquid per bushel. Big distilleries typically run a 28 to 35 gallon beer. We run a 30 gallon beer, and hit a starting gravity around 1.065. So, for 500 gallons of finished mash, we start with 16 and 2/3rds bushels. This is important as bushels are a measure of volume, not weight, and we are working in volumes here. So this means my mash with 61 lb/bushel corn has more pounds of corn than if I used 56 lb/bushel corn, yet it has the same thickness so I know my pumps, agitators, exchangers and hoses can handle it. We start with about 380 gallons of 90 degree F water, and use live steam inject to add about another 55 or 60 gallons worth of water getting it to high temp. With the grain we hit 500 gallons +/- 5 or 10 every time. So for your 600 gallon recipe, as a 30 gallon beer, would be 20 bushels. (20*75%) 15 bushels of corn times its test weight (56 is average, but you should test your grain) = 840 lbs (20*21%) 4.2 bushels of rye (54 is average, again should test) = 227 lbs (20*4%) .8 bushels of malt (38 is average) = 30.4 lbs of malt Use about 528 gallons of water (less the appropriate amount of steam if using steam sparge) These weights are for field grains, not flaked. I'd also recommend starting with a 30 gallon beer and see how your equipment runs it, and thicken/thin it out based off experience. We test all of our grains upon receiving, and update our mashbill in pounds to match the new test weight.

-

Again, the standards are just starting what single malt already means. I would have an issue with a distiller making "Bourbon" but only using used oak barrels. Ya they are innovating, but the standards are there to protect the product definition. If you want to do something that isn't 100% malt, it isn't a single malt. You can already do that, there are already lots of options for labeling in America.

-

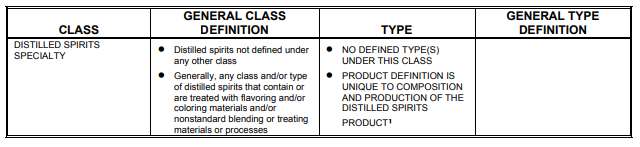

-

Using the public registry, you can see it is not (in the eyes of the TTB) a straight bourbon whiskey, but indeed a whiskey specialty as described above. It also required a formula. See the links attached Parkers: https://www.ttbonline.gov/colasonline/viewColaDetails.do?action=publicDisplaySearchBasic&ttbid=18159001000469 Angels Envy: https://www.ttbonline.gov/colasonline/viewColaDetails.do?action=publicDisplaySearchBasic&ttbid=13093001000246

-

Getting absinthe to louche properly

Tom Lenerz replied to geraldmarken's topic in Absinthe (and other herbals)

What is your total load of botanicals (pounds to PG)? At what proof did you take your tails cut? Did you filter this spirit? -

CFR 27, Chapter 1 Subchapter A Part 5 Subpart C 5.22 (ii) “Corn whisky” is whisky produced at not exceeding 160° proof from a fermented mash of not less than 80 percent corn grain, and if stored in oak containers stored at not more than 125° proof in used or uncharred new oak containers and not subjected in any manner to treatment with charred wood; and also includes mixtures of such whisky.

- 32 replies

-

- 1

-

-

I don't have a dog in this fight, but I'm not sure how adding single malt whiskey to the standards of identity, limits innovation, it just gives America the same classification that many other countries already have. People can do less than 100% malted barley, already as Malt Whiskey or Whiskey Distilled from Malt Mash. Unless I'm missing something here.

-

It just depends if he has a cleaner or not, and how that cleaner is setup. I've had a couple different farmers do seed cleaning for various grains we got, but only one was really setup for it, and for him it sounds like it isn't much work. The others had less efficient setups, and so it was more work. However, the local malt house should have a cleaner and should be able to take care of it. Unless they have a policy for some reason to only take in pre-cleaned grain.

-

Question about separation of distilling area and samples area

Tom Lenerz replied to Jaguiler's topic in Beginners

Do you have an elevator? If so, consider the implications both legal (like in regards to ADA and fire code) and practical (like carrying all of your merchandise up and down and making your customer's walk up and down creating bottle necks) of having a retail space that can only be accessed by stairs for both you and your potential customers. Beyond that, I'm pretty certain they both need separate entrances to the spaces. So a separated 'joint entry' that has doors to each space would work. -

Do you have a short neck? Low headspace seems to be the cause of this issue with one of our bottles. Especially bad with synthetic corks.

-

The list of reasons you cut to proof in the tank is as follows. 1) You only have to do it once, versus 100 or 1,000 or 10,000 times. 2) Consistent proof across all the bottles in the batch. 3) Bottlers are typically designed to fill bottles to a fill line near the top. 4) Minimize possible contamination from the bottling environment by only filling once and capping. 5) Filtering near bottling proof. 6) Reduces additional labor. 7) Probably at least 100 other reasons. If you want to get away with a smaller bottling tank, bottle less in each batch, and bottle more frequently, but this still has many of the same disadvantages, as larger batch sizes will reduce the amount of labor in proofing/cutting/filtering, and increase bottle to bottle consistency.