middleofnowhere

-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Downloads

Blogs

Media Demo

Store

Posts posted by middleofnowhere

-

-

You get what you pay for but these are pretty cheap! Not fast, but would work for what I'm interested in doing for a start up. At $660 the price is right.

-

I'm very interested in their reflux/air cooled system. Seems like a very exciting way to get a lot of reflux.

http://gatlingstillworks.com/index.html

I'm intending to pay them a visit next month (May). That said I'd love to hear feedback from anyone that's using one of their stills. Feel free to PM me if you prefer.

-

Don't get me wrong, I love beautiful distilleries. Polished 12+ columns, wood fermenters, aesthetically pleasing stacks of aging bourbon....I love it. That said I have a dream, and that dream is on a shoestring budget. I know I'm not the first in this situation. Many others have blazed the trail.

I'm curious what everyone's favorite "pieced together" distillery is. I hope to look to these for direction and inspiration. I currently live in Reno, NV but grew up in Missouri. I'm wanting to start a distillery in rural Nevada, and my parents recently were loving enough to go and tour woodhat distillery http://www.woodhatspirits.com/. They took a ton of photos, it seems like a great place. This is a great example of using second hand equipment to make top shelf spirits.

What other distilleries are out there using second hand equipment?

-

My numbers are on track with DeerHammer as well.

I don't see DeerHammer's post.

-

I know in real life I need to either use malted barley or add enzymes. Assume 100% conversion.

The next part of alcohol I'm pulling for this thread on the forum:

56 lbs of corn makes 2.91 gallons of 200 proof alcohol

56 lbs of corn makes 5.82 gallons of 100 proof alcohol

Due to lack of efficiency, cuts, life, etc I'm guestimating one can get 4 proof gallons per 56 lbs of yellow corn? Is this what you see in real life? Again, I'm assuming 100% conversion.

If this is super off, what sort of real world output are you guys seeing off of 56 lbs of yellow corn?

-

This is a week long distilling workshop. There's a pretty substantial discount if two or more people sign up together. Is anyone else planning on attending? I'd like to attend class 18, which is April 11-15, 2016

-

Edit: the title should read "ways to add heat to the mash tun". I can't figure out how to edit the title.

This question is related to my rye topic, also in the general forum. Sorry if it's too similar.

I don't know a lot about commercial mash tuns. I'm only going to have access to propane for heat, I can either use a direct flame under my mash tun or steam inject. Steam injection seems scary, I have no experience with it, and I don't want to blow myself up. The concept of a direct flame underneath is pretty straight forward. I'm intending to do a step mash, so I need to add heat to a thick mess. Obviously this will need agitated/stirred, especially if it's over a direct flame.

Can anyone point me in the right direction for my options on direct flame vs. steam injection. What professional setups exist in the ~6 barrel range?

-

I have really enjoyed reading all this. great contributions.

Hey me too!

-

I don't know that I can provide enough information to solicit advice on an actual layout from folks. We're going to be remote, using two storage containers as our base, likely building a roof/structure in between. As of now we are planning on fermenting in 55 gallon drums, and using a 55 gallon SS drum as our boiler. We are off the grid, water comes from a well, electricity from solar panels, heat from either propane or steam (wood fired).

This is going to be a small operation. I'm curious what examples or resources folks know of pertaining to microdistilleries I can use as references? I've never designed the layout of a distillery; measure twice, cut once.

I realize I'm being vague, please feel free to request information, I'll provide responses to the best of my ability.

-

You should get some Seb-star too and watch your goo liquefy before your eyes.

Do you have any literature on this enzyme?

-

Middleofnowhere. What was your water chemistry like? (enzymes are highly dependent on specific water chemistry to convert)

Did you crack you rye? or Mill it? or ground to flour?

Typically rye is distilled on the grain as lautering or the separation of liquids from solids is not easily accomplished with rye.

All of these factors play an enormous role in your distillers beer being fermentable and easy to work with.

This was a first round, I don't know. I can get a water report from the city.

I milled it to small parts, but it wasn't a flour. I've followed this recipe before with much luck (not a gooey mess, could separate from the grain).

-

I'm attempting to mimic the recipe found in Morrison 1999.

http://www.scocia.com/newsite/Canadian_Whiskey.pdf.pdf

Using their proportions on a drastically smaller scale.

12 lbs raw rye

1.2 lbs malted 6 row barley (for diastolic power)

6 gallons water

rested just rye for 20 minutes at 92 degrees (all temps in Fahrenheit)

raised mash to 149 degrees, added malted barley, added 3 grams Beta enzyme (SEBFlo-TL), let rest for 30 minutes (SG 1.053)

Raised to 180 degrees, let rest for 20 minutes, added another 3 grams of Beta enzyme, let cool outside over night (SG 1.0568).

It's a gooey mess. I pitched yeast but I believe it will still be a gooey mess after fermentation. I'd like to be able to separate the grain from the wash before I run. I can probably water this batch down, but that's not a long term option.

What went wrong? Temps a mistake? Not enough enzyme?

-

I know of a Distillery in one of those prefabbed wooden sheds about 10 / 16.

Have a website or contact info for them?

-

Having been through the TTB process with two different distilleries, I have my doubts that they would approve it. They require some really solid documentation about the building, the lot, the zoning, the lease with the landlord, etc.

The owner of the land and the container will be one of the owners of the distillery. This property is extremely remote, its 1.5 hours to the nearest one horse town. Thoughts?

-

This isn't a joke, though it would have made me laugh before I started seriously considering it.

Two partners and myself are wanting to get started by having our actual distillery in a storage container. Put an emphasis on "micro" here, but having never started a distillery of any sort, does anyone think this can fly? We already possess a large storage container, and can chop holes in the roof, add doors to the back, etc to make it meet whatever requirements necessary.

If no one has heard of this, where should I look to see if this could be pulled off?

-

Maybe check with Hewn Spirits. He is using vintage woods and may be able to give some insight.

thanks!

-

Does anyone know where I can get an answer to this question?

-

I'm in the process of doing the paperwork to license a distillery in a very remote area of Nevada. Water is a valuable commodity in Nevada. I'm curious what sorts of tests, inspections, criteria, etc other distillers must meet for their mash and cooling water in order to be permitted?

From my research thus far this seems to depends on a case by case basis, I'm curious to hear other people's cases.

-

We are wanting to use a new wood that's never been used to flavor whiskey. Is this considered a flavor, and if so does the TTB need to approve it before we proceed with paperwork?

-

I talked to the guy that surplused it today. He said the motor worked when they unhooked it. The RPM are somewhere between 15 and 30. It was used to make ice cream.

-

I can figure out how to alter the agitator, I'm wondering it it will need modified. I have no idea what is needed for a mechanical agitator to move grain around.

-

Right now a partner and I are hoping to start a distillery as cheaply as possible, get a product on a few shelves, and see how things go from there. We weren't planning on buying a ton of equipment, but I just found this surplus dairy equipment and am wondering if it's a deal I shouldn't pass up.

As of right now we are planning on using a 55 gallon SS drum and a 4", 4 plate column still. We were going to mash in the same SS drum, but now there's this beast.

I've been a beer homebrewer for awhile, and understand the mashing process. I'm not sure what mods I'd need to do, and how much they'd be.

No idea if the motor works or not. Any idea how easy it is to replace?

Here's the whole thing, can I just put a burner underneath if the agitator does it's job?

Here's where I get nervous, I don't know a ton about heat exchangers or agitators.

1. Can I head and cool ~150 gallons of mash with a heat exchanger like this? If so what other equipment do I need? I assume circulating boiling or cold water through that would be very slow.

2. That agitator doesn't cover the entire bottom. Will this work for grain, or would I need to replace it with a larger one?

This bottom seems pretty wide/nice. I assume as long as my mash isn't super thick I would be able to let gravity do it's work on draining the tank? I'm planning on fermenting and distilling on the grain.

Any thoughts or advice would be great.

-

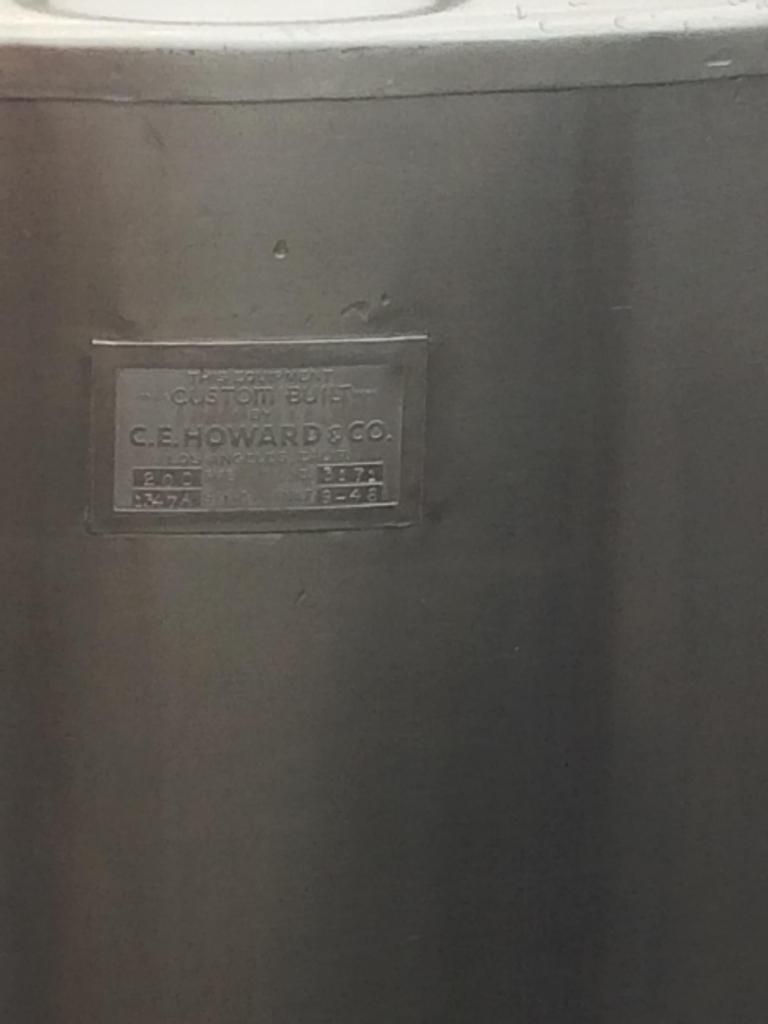

Just found this at a surplus sale. It h was a pump, agitator, heat exchanger, and a 200 gallon capacity. The surplus sale was closed today, so I couldn't get any closer pictures.

Thoughts on value? I'm hoping to use this as a mash tun.

Will this work as a mash tun with minor modifications? Thoughts on price? I can post more pictures of the inside tomorrow.

-

Most of my distillery is used SS dairy equipment that has been modified for my purposes. This place buys cheese factories and sells the parts: http://www.ullmers-dairyequipment.com/

Thanks. Your website didn't have any pictures of your distillery, at least I couldn't find any. Care to share any?

Ideal glycol to water ratio?

in Equipment

Posted

I'm curious what they ideal glycol to water ratio is. The only thing numbers the internet has provided me is either 50:50 glycol to water or 100% glycol. I'd be using this in a double boiler, not sealed. This will be a small setup for test batches and recipe formulations. I would assume a 50:50 glycol to water ratio would allow for the water to evaporate off. Thoughts?

Also, do I need to worry about glycol fumes during any phase? I don't believe so but thought I'd double check.