-

Posts

67 -

Joined

-

Last visited

-

Days Won

2

Trevor last won the day on May 6 2019

Trevor had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Trevor's Achievements

Active Contributor (3/3)

2

Reputation

-

Interresting rticle with suggestionas for standardising Rum labeling: Rum label transparency is of substantial interest to many enthusiasts. No, not whether you can see through the label or not. Rather, transparency in exactly how the rum was made. While the rum world has made great strides towards greater transparency recently, there’s still a great distance for brands to travel. Information disclosure is still a “wild west” situation, with most brands approaching it ad hoc … if at all. This isn’t to dismiss the efforts of those forward-thinking brands who do it well and consistently, but in the industry as a whole, there’s much which can be improved. https://cocktailwonk.com/2020/09/rum-label-transparency-quantifying.html

-

Looking for Partners in No. Virginia. Let's do this!

Trevor replied to Masterofnone's topic in Business Opportunities

So what are you thinking? -

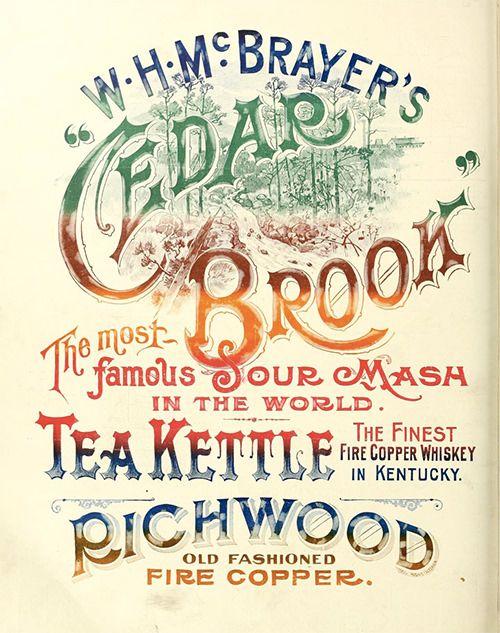

I think the OFC name confusion goes back a long way. Here's a link to a 1895 case that shows they were confused on what it stood for and either way, neither Old Fashioned Copper nor Old Fire Copper are able to be trademarked for the same reason you cant trademark Old Sour Mash. It might also explain why they let the 1880 O.F.C. trademark lapse and created a new OFC trademark. https://books.google.com/books?id=MkosAQAAMAAJ&pg=PA654&dq="Old+Fashioned+Copper"+whiskey&hl=en&sa=X&ved=0ahUKEwiGu9PcnIXiAhWnUt8KHf1UAfEQ6AEITTAH#v=onepage&q="Old Fashioned Copper" whiskey&f=false

-

The term fire copper seems to have come from the brewery process. "steam fire copper" is another variant that used steam. Here area few descriptions: =============================== The boiling of the wort with hops is the next operation involved in the manufacture of beer. The copper is the vessel in which this is carried out. There are two kinds in use, the "fire-copper," which is directly heated by fire, and the "steam-copper," heated by steam. Fire-coppers are built over a brick furnace; the lower end is pan-shaped. Half-way up it widens out slightly, thence to the top the sides are vertical or sloping. The old-fashioned coppers are open, but in many breweries they are closed, and the contents are boiled under a slight pressure. Some brewers prefer to boil pale ale worts in open coppers. Modern breweries are often fitted with steam coppers. Each of these has a jacketed bottom forming the steam-chamber, where steam is injected under pressure, and, the wort thus heated in the copper above. The copper may also be heated by a steam coil placed inside near the bottom. Steam coppers may be open at the top, but often they are closed. The accompanying figure shows the construction of a modern form of a closed copper heated by a furnace. It is provided with stirring gear so that the contents of the vessel may be thoroughly mixed. ================================== Steam-Coppers.—These differ considerably in shape from fire-coppers. The bottom is bellied outwards, and is made of considerable thickness to withstand the pressure of the steam (Fig. 69a). The sides may, as shown in the figure, be carried straight up or they may slightly taper outwards. Attached to and surrounding the bottom of the copper there is an iron dome, which is somewhat larger in size, so that a cavity of from three or four inches, B, is left between its interior and the bottom of the copper. Into this high-pressure steam is admitted by a cock, C, an air-tap being provided to allow the imprisoned air to escape when steam is turned on. This is a very necessary precaution, since, as air is so highly expansible by heat, if its exit were not amply provided for an explosion might occur. A pipe for carrying off the condensed water passes from the bottom of the steamjacket to the steam-trap, D, which latter permits the water to escape but holds back the steam. The wort-pipe, E, passes through the centre of the copper bottom. The steam-copper possesses several distinct advantages over the older fire-copper. It can be heated up before the introduction of the wort, and the wort quickly raised to a temperature which puts an end to all further diastatic action. The readiness with which the heat can be applied or arrested is a point very much in its favour. It is also vastly more economical; a fire-copper, according to Professor Schwackhb'fer,1 only utilises about 30 per cent, of the available heat of the fuel consumed, while a steam-copper utilises 70 per cent., and thus a saving of more than half the fuel employed is effected. ============================ https://books.google.com/books?id=1VvXAAAAMAAJ&pg=PA88&dq=steam+"fire+copper"&hl=en&sa=X&ved=0ahUKEwiftcLO5IXiAhWCdN8KHc0gCvMQ6AEIRTAF#v=onepage&q=steam "fire copper"&f=false https://books.google.com/books?pg=PA88&dq=steam+"fire+copper"&id=1VvXAAAAMAAJ&output=text https://books.google.com/books?id=iIsoAAAAYAAJ&pg=PA441&dq=steam+"fire+copper"&hl=en&sa=X&ved=0ahUKEwiftcLO5IXiAhWCdN8KHc0gCvMQ6AEIPzAE#v=onepage&q=steam "fire copper"&f=false

-

As long as there have been labels on spirits there have been marketing terms to differentiate one product from another. Sometimes they use terms to describe ingredients like Rye, Wheat, Corn or Molasses. "Old" and "pure "were often used and abused to imply age and purity. They also used terms like Bourbon, Monongahela, Irish and Scotch that imply to both a special process and geographic area. Sometimes they used terms like "sour mash", "Sweet Mash" to describe the process used to create the spirit. "Double Distilled", "Triple distilled" were terms referred to the number of times the product was run through the still. Of all these terms, most have survived prohibition or have seen some sort of rebirth as the number of new craft distilleries booms. But one important term has yet to make a meaningful comeback - "Fire Copper". When the continuous patent still was patented by Aeneas Coffey in 1822 it created a revolution in the distilling industry. Before then distillers largely had to use large pot stills to mass produce as they became popular. With an industrial method of producing spirits as a continuous process it quickly threatened many of the smaller spirits producers. These smaller producers needed a way to market to their customers to show their product was a true craft product made in batches in copper stills. "Fire copper" and "Pure Fire Copper" quickly became that term. From the 1850s through the Prohibition in the US the term was frequently seen on labels. After Prohibition the term was largely lost to history. Today about the only remnant is the Old Fire Copper (O.F.C.) label but more often the OFC is said to mean Old Fashioned Copper.

-

Exactly. They take you to a fake museum and nowhere near the distillery. Barralito was closed to tours when I went: Currently, we are closed for visits due to construction on site. We are building a Visitor Center that should be available in January when we will have the facilities for tours. Sorry for the inconvenience, Edmundo B. Fernández, Inc.

-

I would say avoid the Bacardi tour. The other distillery in San Juan didn't have tours operating. The Bacardi tour is fake. Honestly the best part was hanging out on Condado Beach. Costco is a good place to stock up on booze and food. Cuba was a lot more interesting. Actually, Old San Juan was great too.

-

Outdoor wood fired stills for wineries etc?

Trevor replied to Southernhighlander's topic in Equipment

Slick! I've never seen something like this .Very inventive. -

Outdoor wood fired stills for wineries etc?

Trevor replied to Southernhighlander's topic in Equipment

The designer sells the design to fabricators. If you start fabbing these or something similar please send me a message. I'm been trying to convince my cousin who is a welder to try making me a few. -

Outdoor wood fired stills for wineries etc?

Trevor replied to Southernhighlander's topic in Equipment

The base was designed for Montanya Distillers by a company called Resource Engineering Group or REG. There another distillery called Bluewater in Washington that uses the design too. Dodson Harper, P.E., S.E. Principal Resource Engineering Group, Inc. Mail: Box 3725 Delivery: 502 Whiterock Ave., Suite 102 Crested Butte, CO 81224 USA Office: 970-349-1216 Cell: 970-209-3938 dodson@reginc.com www.reginc.com -

Outdoor wood fired stills for wineries etc?

Trevor replied to Southernhighlander's topic in Equipment

Montanya Distillers in Colorado has a copper alembic in a gas firebox you may want to look at. I tracked down the fabricator a while back. Could be converted for wood since the firebox is basically a stove. I like your idea and might be interested. I can send pics and the little info i have if you want. -

I am headed to Cuba and Puerto Rico in November. Does anyone have any rum distilleries, sugar producers or suppliers they would recommend visiting?

-

Was this built by Buzick Lumber?

-

A building collapse at the Barton 1792 distillery in Bardstown sent thousands of barrels of aging bourbon crashing to the ground. Bardstown fire officials said the collapse happened at Barton 1792 after 11 a.m. Friday. : Bardstown, Kentucky fire chief believes the #bourbon from a warehouse collapse @Barton1792 is running into a nearby creek; awaiting EPA arrival. https://t.co/DDfWsMLfb6

-

I'm currently searching for a Trademark. The Patent and Trademark Website help pages aren't the most helpful. So Far here are my best tips. I'm not a lawyer. Please contribute if you have knowledge or experience to share. In general most people will say to hire a lawyer. I would think the best first step is to not waste the lawyer's time and your money by trying to trademark something you yourself could have determined is trademarkable. In general you don't want a trademark that is merely descriptive. It shouldn't be merely a surname. It shouldn't be a geographical place name indicating where you are(in most cases). The best trademarks are suggestive, arbitrary or fanciful. If possible trademark the name words only first (word mark). 1) Go to https://www.uspto.gov/trademarks-application-process/search-trademark-database 2) Click "Search Trademarks" 3) Click "Word and/or Design Mark Search (Free Form) " 4) To search, enter this in the search box and click "Submit Query" 4) Google your desired trademark along with key words like brewery, beer, wine, distillery, whisky, etc. Unfortunately a company can claim a trademark infringement even if they did not register with the Trademark office. Additional info: CLASS 32 (Light beverages) Beers; mineral and aerated waters and other nonalcoholic drinks; fruit drinks and fruit juices; syrups and other preparations for making beverages. CLASS 33 (Wine and spirits) Alcoholic beverages (except beers). CLASS 43 (Hotels and Restaurants) Services for providing food and drink; temporary accommodations.

copy.jpg-r.jpg.6d4a7172a94e4f99cdc6d43a2c6e370c.jpg)