-

Posts

407 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Gallery

Downloads

Blogs

Media Demo

Store

Posts posted by Georgeous

-

-

19 hours ago, Silk City Distillers said:

Is there any reason why you wouldn’t strip more than one batch before you do a spirit run?

Also, with 5 plates available, why didn’t you run it single pass?

Also keep in mind that you likely may not be able to use 5 plates on a whiskey strip - as you’ll easily be above 160 proof - unless you add a lot of water.

Also, had i had used the column instead of stripping run as 51 gallons out of 600 was potential 100% ethanol i guess that would have been ok to run all five plates?

-

19 hours ago, Silk City Distillers said:

Is there any reason why you wouldn’t strip more than one batch before you do a spirit run?

Also, with 5 plates available, why didn’t you run it single pass?

Also keep in mind that you likely may not be able to use 5 plates on a whiskey strip - as you’ll easily be above 160 proof - unless you add a lot of water.

thats exactly what we should have done, dont know the column yet still researching it. How many plates would you recommend starting with? Also as we come from a thumper world how long to rectify? At a certain point it can only rectify so much and the vapors will pass to the column, right? So lets say i only wanted to use 3 or 2 plates , since it feeds from the bottom up the column i guess we would have to by pass the upper two or three plates?

-

19 hours ago, kleclerc77 said:

Yes.

yep thats what i figured

-

On 3/21/2019 at 4:17 PM, JailBreak said:

Couple questions:

1. How are you calculating volume? If it isn't by weight and proof you may be off by several gallons depending on several factors.

2. What kind of still are you running? What is your target ABV off the parrot? Most stills that I'm aware of recommend not running them under 1/2 volume if not more. If you have a pot still and shooting for 70% you will have to do several stripping runs to meet that half-way point. If you have a column still that can give you a decently high proof from a 8% charge, diluting the one stripping run down will be enough.\

This is the main reason some distilleries will often have 2+ stills. A larger stripping still and a smaller 'finishing' still that will accommodate the stripped volume.

1. we have 400L recieving tanks but we also weighed it.

2. we have a 600 gallon pot still with whiskey helmet and 5 plate column. did not use the column as this is new to us coming from a moonshine still with a thumper.

-

On 3/21/2019 at 3:56 PM, Tom Lenerz said:

If you want to improve your yield, you should collect lower than 20% abv.

Meerkat has it covered, all the alcohol you estimated is accounted for, its just that you left it in the still because you had about 500 gallons of mash at 2.5% abv, down from your 600 at 8.5%.

This was already a very long run and just the way we were taught at distillery in virginia was to stop running on stripping run at 20%. When we stopped we were running the still at 98°C / 208°F and were getting a trickle out of the still. for you column experts if i had used the column should i have opened all 5 plates and how long would you let it go with dephlegmator? Until it can rectify no more?

-

2 hours ago, Silk City Distillers said:

Keep in mind, if you are fermenting and distilling on the grain, you need to remove the bulk volume of remaining grain from the total volume to calculate an accurate alcohol yield.

600 gallons of grain-in fermented wash, with 1200 pounds of grain, at 8.5% is not 51 gallons of absolute (100%) ethanol (600 * 8.5% = 51), because you need to net out the weight of the non-alcohol containing grain solids that are hitchhiking along.

At worst case, 1200 pounds of grain into 600 gallons yields 100 "gallons" of solids, and 500 gallons of alcohol laden liquid. Now, this is the worst-case - we've converted a good portion of grain starch to sugar in the liquid, so that weight needs to be removed, but grain germ, pericarp/endocarp, husk, bran, protein/fiber/fat, etc - these need to be removed from the volume - they are taking up considerable space, but do not contain alcohol.

Realistically, you'll be somewhere between 43 gallons of absolute, and 51 gallons of absolute. You can get very clever here, by estimating the non-starch component of your mash-bill and adjusting as necessary.

Just for conversation, let's split the difference - say realistically somewhere around 47 gallons of absolute as the max.

so my almost 100 gallons of 37.7% ABV is correct? Also we did not run this through our column only our whiskey helmet. We came from a 50 gallon copper moonshine still with a thumper to a 600 gallon pot still with a whiskey helmet and a 5 plate 18" column. We havent grasped the concept yet of using a column so we bypassed it for our maiden voyage on this monster. Very new to the whole dephlegmator thing. From what i been reading i probably should have but not sure how much that would have stripped out our flavors yet. Life used to be so simple.

-

6 hours ago, Thatch said:

You are likely correct but only the still manufacturer can tell you for certain. Our stills, one that is direct fire and the other a baine marie require at least a 1/2 charge.

Well I have a 600 gallon still with a 5 plate column I also was told by my manufacturer to use a half charge. so now I'm at the Dilemma do I take my hundred gallons and add 200 gallons of water and run it through the refracting columns ?

-

6 hours ago, Thatch said:

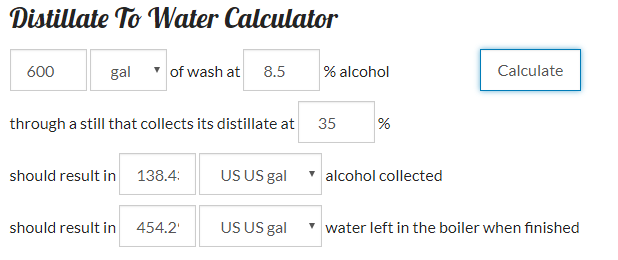

Ok well this is what i was looking for. i came up short about 38.4 US Gallons providing this calculator is correct. Now my Anton Parr Digital Hydrometer has an accuracy of .1. so if i continued to collect to a 35% collective and not stop at 37.7 i may have hit this target

So now i have to redistill to do my cuts. i am now afraid that 100 gallons of stripping run collective is too small for my 600 gallon still, thoughts?

-

7 hours ago, meerkat said:

@Georgeous Sorry, my bad. @Eud is correct. The 37.7 gallons are gallons of absolute alcohol and not proof gallons.

But the conclusion remains the same. I calculated from theory and got 38.5 gallons of absolute, compared with your actual measurements of 37.7 gallons of absolute.

gotcha, but my question in the end is:

if starting with a mash of 600 gallons at 8.5% ABV and my target is to stop collecting at 20% ABV in the parrot for a spirit run targeting 35% ABV of the collective. What volume in Gallons not proof gallons should i expect to collect?

-

8 hours ago, Eud said:

Isn't a proof gallon a tax concept defined as one gallon at 100 proof (50% ABV)?

In which case I think you'd have 37.7 * 2 = 75.4 proof gallons for tax purposes.

so based on this formula i got from ttb

Converting U.S. gallons into proof gallons for tax purposes:

1. Multiply U.S. gallons by the percent of alcohol by volume.

2. Multiply by 2.

3. Divide by 100.

My calculation:

1. 100 U.S. gallons x 37.7% alcohol by volume=3770

2. 3770 x 2=7540

3.7540/100= 75.4 proof gallonsseems low to me. i was expecting higher volume. i actually collected right at 100 gallons of 37.7 % abv. i use a snap 51 digital alcohol meter to get the final reading.

so yes you are correct EUD, but what i am asking is what should i have ended up with? i thought from 600 gallons i would of stripped out a lot more.

-

2 hours ago, meerkat said:

No, what I was trying to say was that within the accuracy of your measurements and my theoretical calculations the results are effectively the same. I don't know how precise your 600 gallon and 100 gallon measurements were, but I suspect there would be some inaccuracy there. Certainly my theoretical calculation was not very accurate. For a start I totally ignored the shrinkage that occurs when alcohol and water concentrations change. I made a couple of simplifying assumptions to make the calculations easier and quicker. My gut feeling is the 37.7 proof gallons that you calculated is probably within 1 gallon of the true value.

Meerkat, i did not have 37.7 proof gallons, after the stripping run i have 100 gallons of 37.7%ABV product

-

2 minutes ago, meerkat said:

@Georgeous What you have achieved is very close to the theoretical numbers. The 51 gallons of alcohol you started with looks right. If you stripped until the spirit in the parrot was at 20 abv then (assuming no reflux was being used) the theoretical strength of the spirit in the still should have been 2.5 abv. Ignoring the shrinkage, if you took of 100 gallons of distillate there was 500 gallons left in the still at 2.5 abv. This would make 12.5 gallons of alcohol left in the still. If you started with 51 then the distillate should contain 51 - 12.5 = 38.5 which is very close to what you achieved.

The reason there are no easy-to-use calculators for these calculations is that the calculations are simply too varied. You can get process simulators that are really aimed at the petrochemical industry, but would handle these calculations, but they are horrifically expensive - typically more than $100,000 and only the largest engineering contractors have them. And they have specialist engineers to drive them.

so my 100 gallons of 37.7ABv is = to 38.5 gallons of 100 ABV?

-

So I used my snap 51 digital hydrometer to take accurate readings out of the parrot. my first runnings came out at about 82% I stopped at 20% and ended up with a hundred gallons of 37.7% collective. I felt this was short in volume

-

You know when you are making beer there are calculators for everything. Distillers have very few, hell i have yet to find a good mash calculator as corn is not on any of them.

So i have a 600 gallon bourbon mash i want to do a stripping run on i plan on collecting all the way down hot and fast no cuts till i got 20%abv out of the parrot. So how do i calculate to determine about how much volume to expect? Now logic tells me i have 600 gallons x 8.5% = 51 gallons of alcohol, but i wont be collecting 100%. My range coming out will start somewhere around 85%ABV and Finishing at 20% ABV. My target is overall of the collection to be about 35%. What would you expect this to yield in volume.

Now i have already done this and i know what i ended up with. I want to know:

1. why is there not stripping run calculators

2. What to expect on a stripping run so i have a receiving tank that can accommodate this

Your thoughts?

-

On 3/12/2019 at 9:44 AM, MG Thermal Consulting said:

G,

How are you keeping the CLT cold? A recirculating chiller?

yes

-

5 hours ago, starcat said:

You need to use Float and Thermostatic Steam traps for this type of application. The one shown looks like an inverted bucket trap. I have seen and dealt with misapplied inverted bucket traps on systems where they could never work correctly and stay primed and respond. They have limited use application wise and will always be trouble on this kind of a system.

Your steam traps need permanent blow down valves installed. I am assuming your servo which appears to be in the infeed line is sized correct for the flow rate. You need air eliminators on your Steam main, and I am assuming your vessel is fitted with a vacuum breaker. Did you say you are not using a return pump of any kind? That I have never seen. Typically shutter mounted exhaut fans are not used in boiler rooms. Instead the fan should bring air into the room with a high relief zone and is generally thermostat activated and in calculation with combustion air.

There is a new Steam Blog as listed on Pro Brewer from a guy who has a good knowledge base:

Can you send me a picture of yours so I can see what your traps look like wood blowdown valves

-

21 hours ago, MG Thermal Consulting said:

Silk,

Sounds about right for the total load.

Do you have a reservoir tank? That cuts the chiller size down in proportion to the amount of chilled water you precool.

Precooling the tank with the chiller running dedicated to the mash cooling until complete will allow recovery so the chiller can be used for the still.

i have a 600 gallon cold liquor tank that i keep at 34°F

-

23 hours ago, Silk City Distillers said:

How much cooling is required to cool 600g mash to pitch temp in 30 minutes?

50-75 tons?

50-75 tons of what?

-

yes my mash pump has 1.5 triclover fittings on it

-

On 3/9/2019 at 2:13 PM, Southernhighlander said:

George,

They are around $3,000.00 I don't know the exact price. I don't do the quoting. My COO, Susan Knapp does the quoting. if you email susan@distillery-equipment.com and ask for a quote for the 2" tube in tube heat exchanger, she will quote it for you. You will need to loop into either your mash tun or fermenter with a mash pump and you will need a pump for pumping coolant, counterflow to the mash. You could loop through your mash tun with the cooling jackets on and you should get a crash cooling time of less than 30 minutes.

Thank you.

Paul

paul, my outlets on still are 1.5" , this is 2" tube in tube chiller. is there a 1.5"? that is awesome looking system though. i will reach out to susan for quote

cheers

-

21 hours ago, Southernhighlander said:

I apologize for not getting back to you sooner. I did not notice your above post until now. Concerning the manifold on top of the inner pot. I see a chines safety valve on the manifold. Many times these chinese safety valves are combination pressure relief and vacuum relief. I would replace the Chinese pressure relief valve with an American made 5 psi pressure relief valve of the proper capacity for the vessel. You should also make sure that you have an American made Vacuum relief valve. I'm not sure what the ball valves are for on top. Is there anything inside where the ball valves connect? Have you asked the manufacturer what the valves are for?

The Chinese Safety valves on vessels jacket must be replaced by ASME section VIII pressure relief valves of the proper PSI rating and capacity to be up to code. I would also instal vacuum relief for each jacket. We are Apollo distributors. I am glad to sell you the correct valve for your needs. Give me a call Monday through Thursday between 9:00 AM and 3:30 PM CST. We will be leaving early Friday morning for the ADI Denver Conference.

so i have no idea what the valves are for either i since removed them and capped them off with triclover covers. on that manifold now are only two things one is the pressure gauge and the other is the pressure/vacuum relief valve

-

20 hours ago, LI Spirits Distillery said:

hi, yes it is!

can you send the specs, i dont see the attachment you mentioned. also where is this located?

-

still available?

-

On 1/17/2019 at 9:10 AM, Southernhighlander said:

Georgeous,

We have Tube in Tube heat exchangers in stock that will crash cool 600 gallons of mash in about 1 hr. 417-778-6100 paul@distillery-equipment.com

Paul, what do these go for? i would like to see pics of what you are talking about. Also what kind of foot print and what else will i need to connect it to my system?

thanks

George

Calculators for Distilling

in General Discussion

Posted

i appreciate that Adam and most likely the avenue we will take with this batch when we redistill it. As for the brewery consultant we have been talking with a consultant distller to come out and familiarize us with the workings of our column. We got the pot distilling down fine, but need to master the column. i have 5 x 18" plates in this beast and yes on a spirit run would probably be over 160 proof. we will take this batch and add 200-300 gallons of water and start with two or three plates and see what we get.