Thatch

Members-

Posts

508 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Events

Gallery

Downloads

Blogs

Media Demo

Store

Everything posted by Thatch

-

Follow @Silk City Distillers questions and advice. He'll get you going to the right direction. BTW, we do many stripping runs on our baine marie prior to doing a spirits run on our direct fire.

-

You are likely correct but only the still manufacturer can tell you for certain. Our stills, one that is direct fire and the other a baine marie require at least a 1/2 charge.

-

-

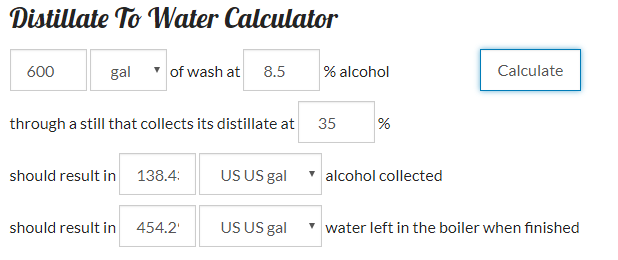

Hillbilly stills has a distillate to water calculator that will give you a good ballpark number. Keep in mind that the numbers provided are theoretical and assume you have collected 100% of you ethanol. https://www.hillbillystills.com/distilling-calculator-s/265.htm

-

No, many do, we do. If you search on "chiller" or "glycol" on this forum you should see many questions and answers on this topic. @MG Thermal Consulting is a regular contributor to this forum and that is his business.

-

Clarification on Title 27, 19.54 Other businesses

Thatch replied to jcameron's topic in Federal Gov't

No The space would need to be secure. Keep in mind that the TTB is interested in protecting revenue. As long as this space does not have easy entry by others there should not be a problem. We have our distillery inside a malt house. The malt house is within the confines of the DSP. There is also another company within the building but not within the confines of the DSP. The TTB may be your lesser challenge. You need to talk to your AHJ about what their requirements are based on how much storage of flammables you require. -

How American Distilleries Are Transforming into Tourist Destinations

Thatch replied to Foreshot's topic in General Discussion

Sounds like you have a pretty good grasp of how to attract traffic. I think I understand rack cards. This would be as generally seen in a motel lobby, right? Where do you hang your posters? What sort of checkpoints are you referring, are these border checkpoint between the US and Canada? How do you get article mentions? Do you send out frequent press release? What sort of travel mags are you referring to and are you paying for ad placement in the mag? -

Can you have an assistant distiller under drinking age?

Thatch replied to Rum's topic in General Discussion

Looks like you might be able to but you should also check with your insurer. 1. What is the minimum age requirement for serving alcoholic beverages? Answer: Although it is unlawful for any person under the age of 21 years to have in her or his possession alcoholic beverages, this does not preclude the employment of any person 18 years of age or older in the sale, preparation, or service of alcoholic beverages in any establishment licensed by the Division of Alcoholic Beverages and Tobacco or the Division of Hotels and Restaurants. Generally, it is unlawful for any vendor licensed under the Beverage Law to employ any person who is under 18 years of age. However, there are certain exemptions that may be found in F.S. 562.13. -

Here are the names I would recommend you check for new equipment. Quadrel Ohio, CTM Ohio, LSI New Jersey, New Jersey Machine New Hampshire, Label-aire California There are many others but the ones I have listed have been around for over 20 years each and have always built solid equipment that needs little service. They all sell through a dealer network which are generally marking systems companies and pressure sensitive label converters.

-

This is a fantastic price from a good company (Label-aire) that you would likely be able to get service from. This looks like it might meet your needs. Plus it's in Kentucky which is reasonably close in you. https://www.bid-on-equipment.com/packaging/used-label-printing-equipment/101142~label-aire-2115st-pressure-sensitive-labeler.htm

-

Bid-on-equipment.com has hundreds of used app!icators. There should be a front back amongst them. They don't really wearout. I'll send you a list for who makes new this evening

-

Most applicator manufacturers make what you need. The best starting point is your current label supplier if they are local. Most pressure sensitive label suppliers sell, install and service applicators. If your guy is clueless, let me know and I'll provide a list of names. Send them the video, it explains what you need.

-

Sorry, I cannot come up with a way to keep the speed you need without doing two labelers. This would also require you having your back and front labels on separate cores. Like this:

-

Then I have misunderstood. Apparently you want to put all your labels on simultaneously, is that correct? Is this two labels or 4 labels? Again, just tell me what you want to do, there is likely an applicator that will do it.

-

Like he said.

-

I didn't want to hijack the poor gents story about:: I recently got the bad new myKothe 250L 60 gallon electric still is drawing enough power to change my commercial class and I'm about to experience an almost 1000% increase in electric uses. However since a lot of new folks read this forum I would like to give a vote to electric. We have two electric stills. One is a baine-marie which is our strippng still and the other is direct fired. We are fortunate or unfortunate depending on how you look at things. We use a lot of electricity since we are a malt house as well as distillery and we are also an add-on to an existing company. In any event, we pay a little over 5 cent/Kwh for electricity. So, when I do a 20 hour Vodka run on my 500 liter spirits still that is equipped with 18 kw heaters it costs me less than $10 for the run. And, I am sqeezing out 190 proof to the very end. If you do the math, you will say: AHA, he is wrong! But, my still does not run its heaters full out except for heat-up. I am generally at 9-11 Kwh. The cost of electricity is just another thing you need to check along with water, sewer, occupancy, etc before deciding on your location and equipment. For me, even though I have natural gas available I will likely stick with electric when it comes time to upgrade. BTW, we use a natural gas tankless water heater for mashing.

-

Okay, I think you mean a front and a back label. You could use something simple like the Primera AP550 and have your label manufacturer alternate your back and front label so that you simply turn the bottle over to apply the back label.

-

In a former life I designed and built label applicators. Is this to be an automatic system for filling, labeling (1 side, 3 sides, 4 sides) and cartoning? Describe what your work flow should look like.

-

We stir it in with a mash paddle. The grist hydrator does a lot of the work.

-

Lauter grant. When using a pump to move wort from the lauter tun to the kettle, it is easy to pull liquid from the tun faster than the grain bed wants it to flow, compacting the bed and causing a stuck runoff. ... A lauter grant is simply a vessel that collects the wort from the lauter tun. Sorry, no vegemite here Mate

-

We don't treat or dose the water for PH. We subscribe to the theory that a healthy yeast pitched in sufficient quantity into well aerated wort will likely not need it. That could be quite different depending on what your yeast provider thinks is "best practice". We also feel it to be important to manage the fermentation temp. Our fermenters are closed and jacketed. We crash with glycol. To your earlier question on a wort grant. We used a milk can practice pot still that happens to have the right size fitting for our pump . This is after collapsing our grain bed more than once. This works great for us for lautering and sparging

-

I'm not sure that you need a hot liquor tank. This is from a previous post I made. Happy with our A.O. Smith https://www.build.com/ao-smith-atio-910-an/s1329791?uid=3167497 Heavy Duty, industrial, really does the job. Our water temp is 47 now and will get lower. I guess it all depends on how much you want to mash. Our tun is 550 gallons and we are 100% barley malt. We use a grist hydrator and the flow rate from the tankless heater is what we need to match the water flow with the malt flow and prevent clumping.

-

Thanks, that was tongue-in-cheek. I'm amazed that a company using rice in their beer would poke fun and another using corn syrup. Our distillery in located within a malt house and we sell malt to many microbrewers. You can make great beer or hooch without any adjuncts.

-

Is a tasting room a must for your distillery?

Thatch replied to mattabv's topic in Distillery Tasting Room

I assume you are growing your own raw ingredients. If so, you have a great story to tell. I would put your tasting room in a pole barn on your farm. Before getting into the business I visited many distilleries. Some were in very hard to get to places on single lane roads yet they had people coming and going the whole two hours that I visited. The grain to glass idea is very interesting to a lot of folks. Most of the tours I have been on had a Groupon that alerted me to the distillery. -

I more outrage about their rice. How about some barley malt. Has Bud become rice beer?